The life cycle of honey, from its collection at farms to its dispatch to customers, is meticulously overseen at KK Natural to guarantee hygiene, safety, and quality. This comprehensive process encompasses collection, testing, processing (including melting, filtration, homogenization, and moisture reduction), packing, and storage in our warehouse. Each step is precisely defined and documented to ensure robust controls and exceptional outcomes. KK Natural proudly holds multiple globally recognized certifications, including BRC, TSH, FSMA, ISO 22000:2005, and Non-GMO, which further enhance our quality control measures.

1. Honey Collection

Our trained field collection staff collects honey directly from the beekeepers on their farms within 7 days of honey harvesting. Each container is sequentially marked, providing comprehensive details about the beekeeper and the farm’s location. Initially, all the collected honey is transferred to our local collection depot, situated within 50 kilometers of the honey production area. These temporary sites serve as collection points before the honey is forwarded to our central depot or processing unit. These centers also serve as information hubs, offering technical guidance and support to the farmers. Through this meticulous process, we ensure a complete record and traceability of the beekeeper and honey, maintaining its origin. Additionally, all the honey collected is GMO-free.

2. Raw Material Inspection & Test

The honey received from farms is assigned a unique batch number for accurate identification, and a composite sample (drawn from each container) is forwarded to our in-house laboratory for thorough testing. Our testing regimen includes Organoleptic sensory evaluation, comprehensive chemical analysis, heavy metal assessment, and sugar profile tests, all aimed at verifying purity, detecting contamination, and ensuring compliance with honey standards (Residue monitoring plan). The acceptance of honey is contingent upon the test results aligning with the applicable quality standards.

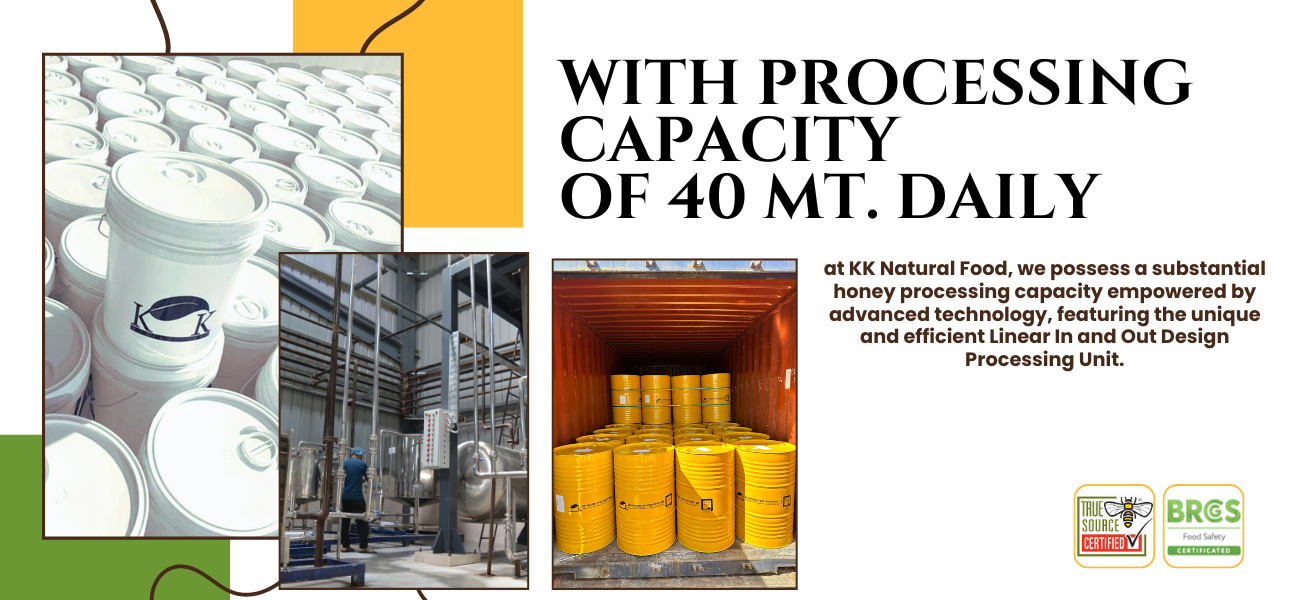

Subsequently, the approved honey is utilized for batch planning, aligning with customer specifications such as color, floral source, Fructose-to-Glucose ratio (F/G), etc. The approved material is then allocated to production for processing. Our standard batch sizes range from 20MT to 40MT, tailored to meet specific customer requirements.

3. Honey De-Crystallization & Filtration

The initial stage in honey processing involves melting it for enhanced manageability. This process takes place within a purpose-built stainless steel chamber equipped with hot air as the heating medium, complemented by diffusers featuring air circulation baffles. Collection trays are situated below to gather the melted honey. Subsequently, the honey is sieved through mesh filters to eliminate any unwanted substances.

Our facility is equipped with tanks boasting a 20 KL (kiloliter) capacity, capable of accommodating up to 28 metric tons of honey simultaneously. These tanks are outfitted with stainless steel agitators (of the propeller type), incorporating slow-speed motors to homogenize the honey into a cohesive batch of 20 metric tons.

4. Moisture Reduction and Homogenisation

The honey extracted from the melting chambers is directed to stainless steel storage tanks made from raw SS304 material, with a capacity of 25 metric tons. These tanks are equipped with stainless steel three-blade agitators, employed at a slow speed for homogenizing the honey. To achieve vertical homogenization, the honey is circulated from the bottom to the top within the raw tank.

The process of dehumidification and moisture reduction entails reducing the moisture content to less than 19% through a heat exchanger and vacuum cone. Honey from the raw tank is fed directly through the vacuum cone, with the flow regulated using a flow meter and valve. The honey exiting the vacuum cone is assessed for moisture content to confirm it’s below 19%. Subsequently, the honey is transferred to finished tanks, and moisture levels are monitored at 30-minute intervals to ensure consistent moisture reduction.

Advanced processing facilities incorporate flash heating and cooling units, filtration systems, and pumps that transport the final product to settling tanks. After allowing the honey to settle for a designated period, it undergoes comprehensive parameter testing in our laboratory to meet specified requirements.

5. Packaging & Warehousing

The honey is held within 25MT finished tanks for settling before being packaged either in bulk or retail quantities. In the case of bulk packaging, honey is directed through a final 80-mesh sieve filter and filled using automated machines into 50Kg food-grade plastic containers or 300Kg epoxy-coated MS drums.

For retail packaging, an additional de-waxing and filtration process is carried out before filling. Our automated filling line enables us to pack honey in sizes ranging from 5gm to 25Kg, utilizing food-grade PET or glass bottles, as well as buckets, based on specific requirements.

During the filling process, samples are collected and sent to an external lab for final testing. Our expansive warehouse is equipped with a computer-controlled inventory system, streamlining the process for efficient and well-organized shipment of all honey packed by us.

Quality is the main essence of our group.

We have an advanced in-house laboratory equipped to conduct essential chemical and microbiological assessments, including tests for antibiotic residues and C4 sugars. Our lab is outfitted with cutting-edge instruments such as EA-IRMS, LC/MS-MS, HPLC, Gas Chromatographs, ELISA, Brookfield Viscometer, Spectrophotometer, Honey Colour Grader, and Water Activity Analyzer. Additionally, our team of technically skilled and experienced scientists oversee the analysis of honey, adhering to both national and international standards (USFDA, EU Codex, FSSAI, AGMARK & BIS).

The laboratory employs internationally recommended and validated methods of analysis endorsed by AOAC, CODEX, and EU. We also utilize standard national methods outlined by BIS / FSSAI, ensuring accuracy and reliability in our testing procedures.

WE HAVE COMPLETE TRACEABILITY OF OUR HONEY FROM “FARM TO FORK.”

Certifications & Accreditation

Our products have undergone comprehensive evaluations, aligning seamlessly with the precise directives and prerequisites of the International Standardization. Our commitment to upholding regulations, practicing sustainable harvesting, and ensuring top-notch quality throughout the honey and bee products’ procurement, filtration, and processing has earned us the following esteemed certifications.